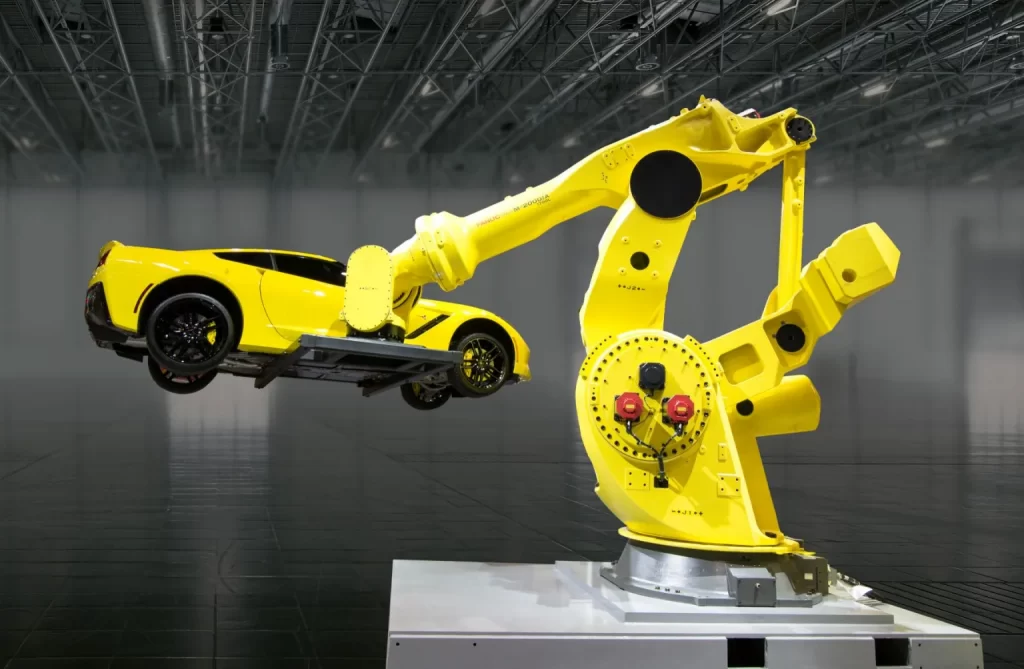

The incorporation of robotic arms in industrial automation is an enormous force transforming the landscape of production and manufacturing processes. Thanks to the advancement of technology, robotic arms, often referred to as Arm robot industrial, have become indispensable instruments, delivering incredible precision, efficiency and security across a variety of industries. This article delves into the numerous capabilities of robotic arms, examining the impact they have on modern business operations as well as the growth of industrial automation in Australia.

Robotic arms, also known as robot arms are versatile mechanical devices that mimic human arms’ functionality but with greater precision and endurance. These automated solutions have found wide-ranging applications in industries like automotive manufacturing electronic assembly, pharmaceuticals and many more, because of their capability to complete complicated, repetitive tasks with amazing precision. Robotic arms are able to be integrated into diverse production environments. The fact that they can be programmed allows the arm to adapt to various operating requirements and provide the flexibility of motion.

The robotic arm an essential component of modern automation. It is an advanced kinematic chain made up of joints that can move, capable of rotating and performing linear displacements with remarkable ability. This lets robotic arm traverse complex spatial configurations and manipulate objects with a meticulous attention to detail, all while ensuring optimal safety for humans. In response, robotic arms are now considered to be indispensable by industries. They can streamline production and increase efficiency.

One of the most distinctive features of robotic arms is the utilization of end effectors, which are the functional equivalent to human hands. These end effects, that are generally designed to accomplish specific tasks, determine the scope of applications for robotic arms. Robot arms equipped with end effectors that are specialized for specific tasks can be able to complete a variety. From lifting and gripping heavy objects to carefully assembly of intricate components, robotic arm with end effectors which are specially designed are able to accomplish these tasks with unparalleled precision and reliability. For more information, click Robotic Arm

Integration of robotic arms into industrial automation has created the beginning of a new era of productivity and technological innovation. Businesses can enhance their processes for manufacturing by taking advantage of the capabilities of robot arms. They can also minimize human error and improve the quality of their products. The seamless coordination between robotic arms and automated systems have led to significant advances in efficiency.

The transformational impact of robotic arms extends beyond simple automation. It is a fundamental change in the definition of industrial processes. The integration of industrial robots have improved manufacturing workflows and set the stage for completely new methods of production. Robotic arms can be used in difficult and hazardous conditions. This has enhanced the safety of workers, while unlocking new opportunities to perform complex manufacturing processes.

Furthermore, the evolution of robotic arm technology has led to the emergence of new end effectors that are that are specifically designed to meet demands of industries. These advanced end effects, that have modern gripping and sensing technology, have widened the capabilities of applications that robotic arms can perform.

Australia is now embracing the potential for robotic arm automation. This provides businesses with the opportunity to improve their capabilities and competitiveness. The integration of robotic arms to industrial workflows has the potential to sustain expansion, improve overall productivity, and revolutionize the way that manufacturing is conducted. Robotic arms are set to revolutionize industrial automation by focused on precision engineering and efficiency.

In conclusion, the introduction of robotic arms, or industrial robotic arms, is an important step in the development of industrial automation. The precision, adaptability, security, and flexibility of robotic arms has reshaped manufacturing possibilities in our modern age and gives businesses an edge on a market that is increasingly competitive. As Australia embraces the transformative potential of robotic arms, businesses stand to profit from improved productivity, efficiency in operations, and technological innovation, highlighting the crucial role played by robotic arms in defining the future of automation in the industrial sector.