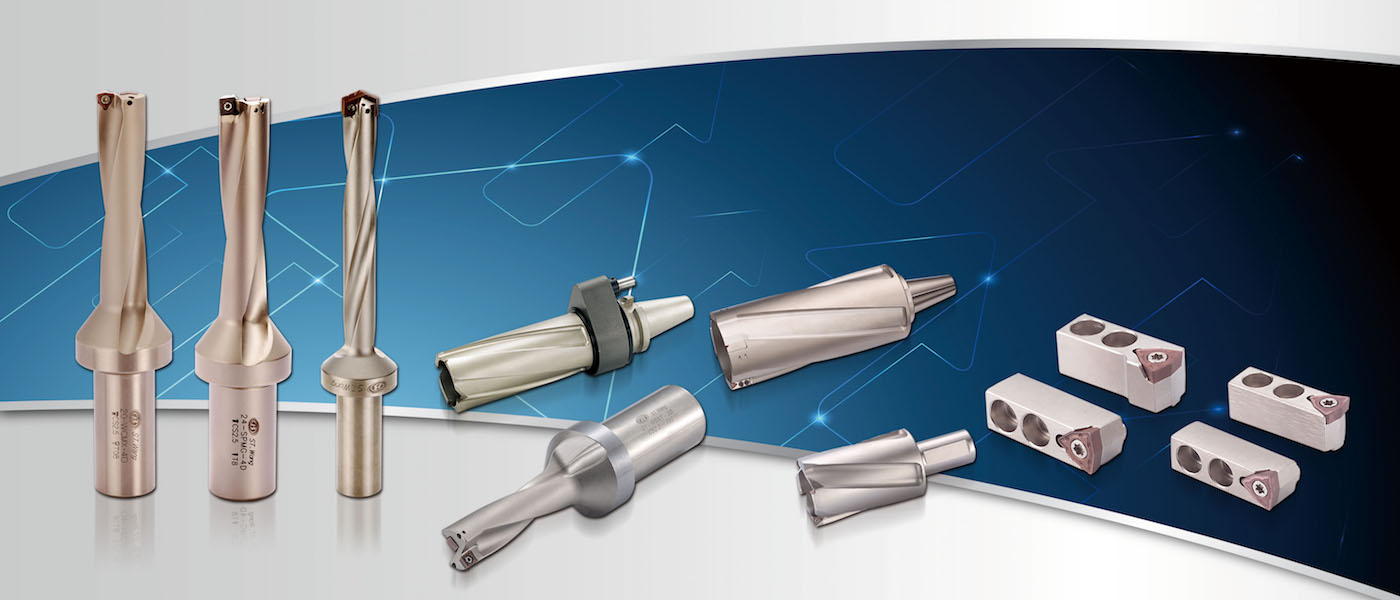

In the past the machining process was about reliability, precision, and speed. But in today’s business environment efficiency is a must. Tools you use directly have an impact on your profits whether you’re manufacturing components for aerospace, automotive parts as well as high-tech electronic products. Indexable drill, high speed drill, tungsten carbide end mills, and threading insert can make a big difference.

Image credit: stwang-tw.com

These aren’t simply updates of older tools. They are a more efficient way to work, as they cut down on time and cost and deliver better outcomes. Let’s examine how each is helping manufacturers drill deeper and cut more efficiently, as well as finish faster.

Indexable Drills: More Holes, Less Hassle

Drilling large holes could be costly and time consuming. Solid drills were slow to wear out, needed sharpening and could slow down production lines. That’s why more machinists are switching to the indexable drill. If the tool gets dull instead of replacing the whole tool simply change the cutting elements.

What makes indexable drills distinct is their effectiveness. These drills are made to perform heavy-duty and have longer runs. They also require little maintenance. With replaceable inserts, you can reduce waste, lower tool inventory, and keep machines running longer. SHANG TZANG WANG ENTERPRISE, CO., LTD offers disposable core-stays that provide reliable performance for large-diameter applications. For shops that perform repetitive hole drilling this upgrade can help make it easier to work for hours every week.

High-Speed Drills for Modern Needs

High-speed drills are used in a production setting where time is the most important factor. They are designed to work fast and accurately without sacrificing speed. They are a great choice for hard materials and speedy cycles. They’re utilized in everything from precision medical components to automotive parts that are high-volume.

Modern high-speed drills come with modern coatings and optimised flute designs that decrease heat and friction, and increase the lifespan of the tool. This means less damage more tool maintenance, and more parts out the out the. If you’ve ever had to deal with a damaged drill in the middle of your work switching to high-speed drills could be a great moment of discovery.

Tungsten Carbide End Mills: Reliable Performance Cut After Cut

When it comes to milling carbid end mills made of tungsten are the most reliable tools on the shop floor. These end mills are known for their heat resistance and hardness. They can also break through tough materials with no loss of edge sharpness. These tools provide consistent results, whether you’re finishing small corners or roughing large areas.

What makes tungsten carbide end mills unique is their flexibility. With a variety of flute counts, angles of helix and coatings, they can be customized to suit a diverse variety of applications from titanium to aluminum. For those who require accuracy and durability, carbide end mills are the perfect balance between the removal of material and clean surface finishes.

Threading Inserts: Tiny Tools, Big Impact

Threads may seem to be just a small aspect of the process, but it’s actually one of the most important. A thread that’s not properly made can ruin a part that was otherwise perfect. This is why a quality threading insert is important. These tiny, interchangeable tools are specifically designed to cut internal or external threads with incredible accuracy and consistency.

The threading inserts are more consistent than traditional taps or dies. They give the same results over many cycles. The tool can be indexed to the next cutting edge when one edge has become dull. It’s not necessary to take it out or restart. It’s simple, tidy and affordable. Not only do machinists appreciate threading inserts for their speed, but also for their dependability. With the correct insert you’re assured that your threads will fit right the first time. There will be no second passes, no rework, and there is no worry about part rejection.

The Bottom Line

In modern machining, time is an asset you shouldn’t waste. The most efficient shops of today have shifted to smarter tools and more flexible solutions for tooling. The cutting tools that are advanced aren’t just better at accuracy, they streamline workflows, reduce the time between changeovers, prolong life and enhance the usability. The result? It means that less time is spent trying to solve problems, so more time is spent providing high-quality components. In an industry where higher demands and smaller margins are standard and tools that are more efficient gives manufacturers the edge they require to remain in the game.