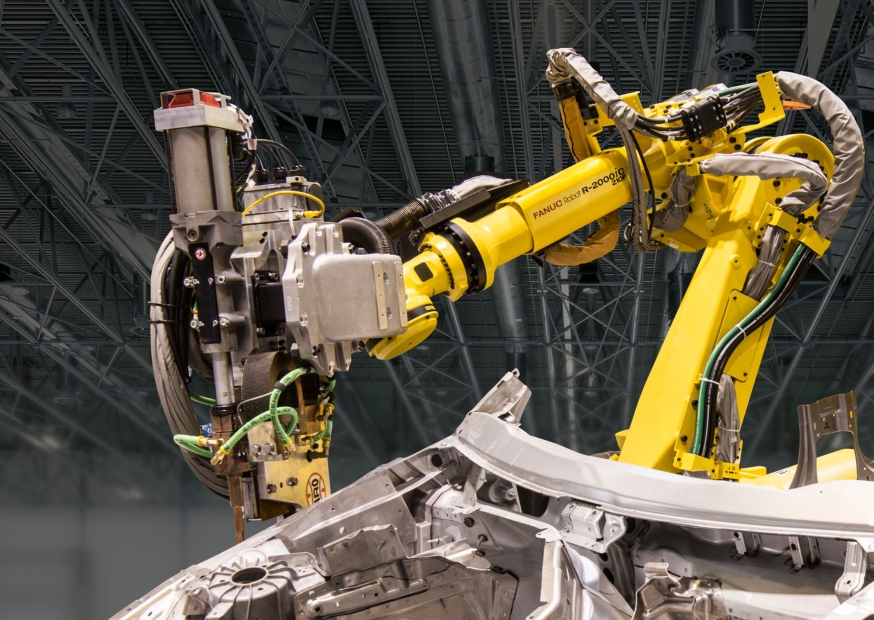

In the midst of modern manufacturing, robot arms are revolutionizing the rules of production, blending precision, safety, and efficiency in ways that were unimaginable. These marvels of the mechanical realm – sometimes known as robot arms have become essential to industries across the globe, motivated by the need to cut operating costs without compromising on quality. Robotic arms are being integrated into production lines to reduce costs and improve security. Let’s examine how these groundbreaking machines are reshaping the landscape of industrial production.

Image credit: automatedsolutions.com.au

Cost efficiency is a major factor behind robot arms’ widespread use. Factories are constantly under pressure to minimize production errors, decrease material waste, and lower the risk of workplace accidents. Robotic arms are specifically designed to combat these challenges. Robots can eliminate costly errors and decrease the amount of raw materials through performing repetitive tasks more efficiently than humans. In high-volume industries such as automotive manufacturing, robot arms guarantee perfect assembly through precise welding and parts placement. This accuracy can translate into significant savings as less defective items mean less rework and waste.

The safety of robotic arms is an important element. A lot of manufacturing processes, such as handling dangerous materials or using heavy machinery can be dangerous for human workers. By using robot arms, businesses can remove workers from hazardous environments. This minimizes the possibility of injury at work. Robot arms, created as a kinematic chain with moving joints, mimics the capabilities of a human arm, however it is free of the threat of physical harm. Equipped with programmable end effectors essentially robotic hands These machines are able to perform tasks like spinning, grasping or welding under conditions that are hazardous for humans.

The versatility of robotic arms makes them a game-changer across diverse industries. Robot arms can adapt to numerous tasks, from assembly for automobiles to electronic production. Because they are programmeable, they can to perform intricate operations like machine tool tending or painting, as well as fiberglass applications, with a remarkable accuracy. In the field of warehousing, robot arms have revolutionized palletizing by automating the process of loading items onto pallets with accuracy and speed. Automation increases productivity and reliability because robot arms work constantly without fatigue.

One of the most fascinating advancements in this field is the growth of collaborative robots or cobots, which are able to work with human workers. Unlike traditional industrial robots confined to isolated cells. Cobots fitted with robotic arms have been designed to allow safe, seamless interaction with humans. A cobot’s robotic hand can be utilized to complete routine tasks like heavy lifting in factories, which means that human workers can free to perform more demanding duties. This type of collaboration boosts productivity while also ensuring a safe working space, since cobots are programed to stop or modify their actions if a person is within the vicinity.

The significance of robotic arms extends beyond safety and efficiency, into the very foundation of modern manufacturing. They are essential for industries that require extreme precision in processes such as welding, assembly or material handling. For instance, in manufacturing of automobiles, a robot arm can move and rotate components during assembly, ensuring the perfect alignment of parts without human intervention. In electronics, robot arms manage delicate components carefully, minimizing damage and improving output quality.

As the world’s industries continue to develop, robotic arms’ role will continue to grow. They’re an integral part of manufacturing’s future due to their capacity to reduce costs, improve safety and adapt to different tasks. Combining cutting-edge technology with human ingenuity Robot arms are not simply tools. They’re part of development, accelerating innovation and changing our way of building the world around us.